Environmental Initiatives

Through its business activities, products, and services, the Cold Chain Solutions Company of the Panasonic Group pursues its environmental vision, Panasonic GREEN IMPACT, to contribute to a better quality of life and a sustainable global environment.

Cooling food should not come

at the expense of warming our planet.

By developing and providing

environmentally friendly products,

we will help reduce greenhouse gas emissions.

We can ensure the quality and safety of food by maintaining appropriate temperatures during temporary storage, transportation, and sales processes. However, our commercial refrigerant products, including display merchandiser cases, should not contribute to global warming.. We are actively engaged in the research and development of products that utilize low global warming potential (GWP) refrigerants. As a manufacturerseller of refrigerant-based products, we recognize this as our responsibility. In particular, HFC-free condensing units that use CO2 refrigerant—a natural refrigerant—are becoming increasingly popular, with cumulative shipments exceeding 30,000 units.* We are committed to reducing greenhouse gas emissions by offering a broader range of evnrionmental friendly products worldwide.* As of the end of February 2025

Refrigerants and global warming

Selecting a natural refrigerant

CFCs were once widely used but were phased out under the 1987 Montreal Protocol due to the damage they cause to the ozone layer. The protocol mandated a reduction in the use of CFCs and other ozone-depleting substances, which led to the adoption of HFCs as alternatives. Although HFCs do not harm the ozone layer, they have a significant impact on global warming. To address this issue, the Kigali Amendment to the Montreal Protocol was adopted in 2016 to further reduce the use of HFCs.

In this context, natural refrigerants such as CO2 and ammonia, which have a low environmental impact, are gaining attention. In particular, CO2 refrigerant is recognized for its excellent environmental performance, as it is non-flammable, non-toxic, and very safe.

The global shift towards refrigerants with the lowest possible global warming potential(GWP) is becoming increasingly important..

| Next-generation refrigerants | low GWP (Global Warming Potential) refrigerants | HFC alternative fluorocarbons | ||||||

|---|---|---|---|---|---|---|---|---|

| CO2 | Ammonia (R717) | Isobutane (R600a)※ | R448A | R449A | R407H | R410A | R404A | |

| Ozone Depletion Potential (ODP) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Global Warming Potential (GWP) | 1 | <1 | 3 | 1390 | 1400 | 1500 | 2090 | 3920 |

| Increasing Flammability | No Flame Propagation | Lower Flammability | Higher Flammability | No Flame Propagation | No Flame Propagation | No Flame Propagation | No Flame Propagation | No Flame Propagation |

| Increasing Toxicity | None | Higher Toxicity | None | None | None | None | None | None |

- United Nations Environment Programme (UNEP)

Environmental technologies of Cold Chain Solutions Company.

Development of products that utilize CO2 as a refrigerant

As part of our cold chain business, we developed the world's first two-stage rotary compressor compatible with CO2 refrigerant in 1999. We started developing products using CO2 refrigerant around 2005, which culminated in the launch of Japan's first HFC-free condensing unit using CO2 refrigerant in 2009. The product was officially released in 2010. Despite the technical challenges associated with CO2 refrigerant, including difficulties in handling due to high operating pressures, we successfully mass-produced HFC-free condensing units with outstanding environmental performance. This achievement resulted from years of fundamental research and a trial-and-error approach during demonstration experiments.

Our HFC-free condensing units are highly energy efficient, using 25.4% less electricity annually in freezing mode and 16.2% less in refrigeration mode compared to units that use HFC refrigerant. We are currently expanding our range of products that utilize HFC-free refrigerants, including small merchandising display cases and chest freezers.

Additionally, Hussmann Corporation also offers a wide range of products compatible with CO2 and other low-GWP refrigerants as part of Evolve Technologies, a comprehensive solution that encompasses everything from manufacturing to installation and maintenance.

- * Average of values measured across six stores, R404A condensing unit: Inverter multi-unit, Electricity-CO2 conversion factor: 0.000579 t-CO2/kWh (Published on November 30, 2015), Refrigerant leakage rate: 16% (METI Review of Emissions from Use of Refrigeration and Air-Conditioning Equipment dated March 7, 2009)

Refrigeration system that uses CO2 as a refrigerant instead of Freon.

Hussmann Evolve Technologies roadshow

Striving for energy-saving efficiency.

The Cold Chain Solutions Company has been committed to energy efficiency improvement for many years. The RE Series of merchandising display cases, launched in 2024, have improved energy-saving performance by adopting a high-efficiency cooler and enhancing the air curtain efficiency. In particular, the reach-in low temprature merchandising display case with vacuum insulated glass (VIG) doors have reduced energy consumption by approximately 33%*1 compared to the previous series. In addition, by combining store controllers, freezers and refrigerated equipment can be centrally managed, allowing for the monitoring of cabinet temperatures while automatically controlling energy efficiency.

The LV Series commercial freezers and refrigerators have reduced energy consumption by approximately 29%*2 compared to the previous series, thanks to a newly designed cooling unit and improved insulation performance.

By reducing energy consumption, we contribute to the reduction of greenhouse gas emissions.

- 1. Comparison between the EV Series (with triple-glazed doors) and models with VIG energy-saving doors Merchandising display case: FLD-EV0377LA x 4 units, Condensing unit: OCU-NL1501F 6,300 W (Refrigeration capacity at an evaporating temperature of -40°C and 50 Hz), Glass surface heater: Activated only during defrosting to prevent condensation on the glass (Defrosting cycle: 30 minutes per cycle, twice a day)

- 2. When comparing equivalent models of the KB and LV Series using the measurement method based on JIS B 8630: 2009

Merchandising display cases from the "RE Series."

Commercial freezers and refrigerators from LV Series

Initiatives at the Oizumi site in Gunma

Implementation of cogeneration

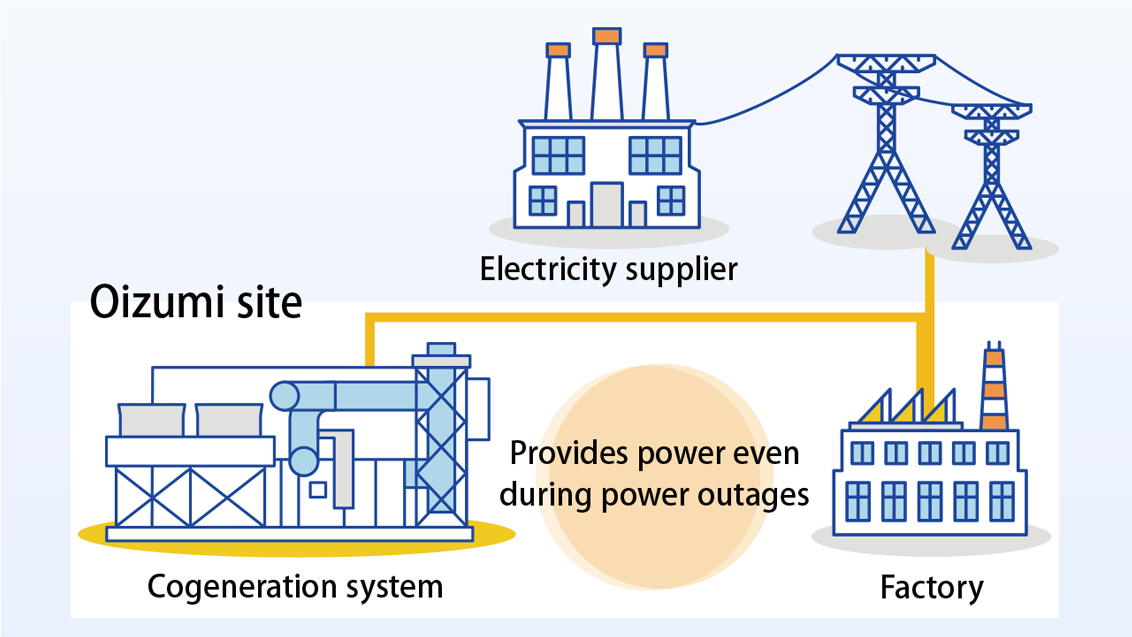

The Oizumi site in Gunma, home to the main factory of the Cold Chain Solutions Company, has implemented a large-scale gas cogeneration system to enhance energy efficiency.

After the first plant opened in 2020, the second plant started operations in 2024, achieving a high level of energy self-sufficiency. In addition, the thermal energy from the exhaust and cooling water generated when the gas engine powers the generator is used to generate steam in the exhaust heat recovery boiler. The steam generated is used in production lines and as a heat source for air conditioning in offices and factories.

As a result, energy conversion efficiency has improved to up to approximately 76%, bringing us closer to carbon neutrality.

Electricity from the cogeneration system is also expected to serve as an emergency power source in case of a power outage due to a disaster or other causes.

Gas engine cogeneration system

Capable of supplying power even during extended power outages