Cold Chain

in Daily Life

Fresh agricultural and marine products are delivered to homes from various production areas, while a wide variety of cold drinks and sweets are displayed in convenience stores and supermarkets. Freezers and refrigerated equipment, leveraging cooling technologies are essential to our lives. The roles of the cold chain and its supporting technologies are outlined here.

What is the cold chain?

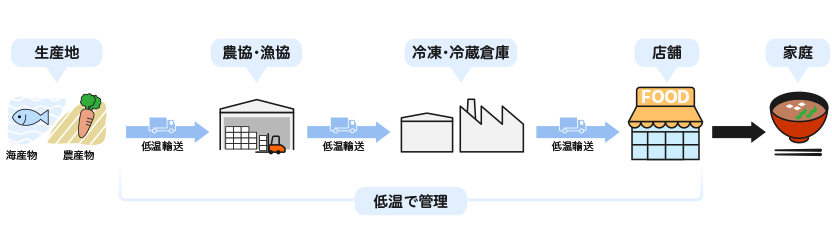

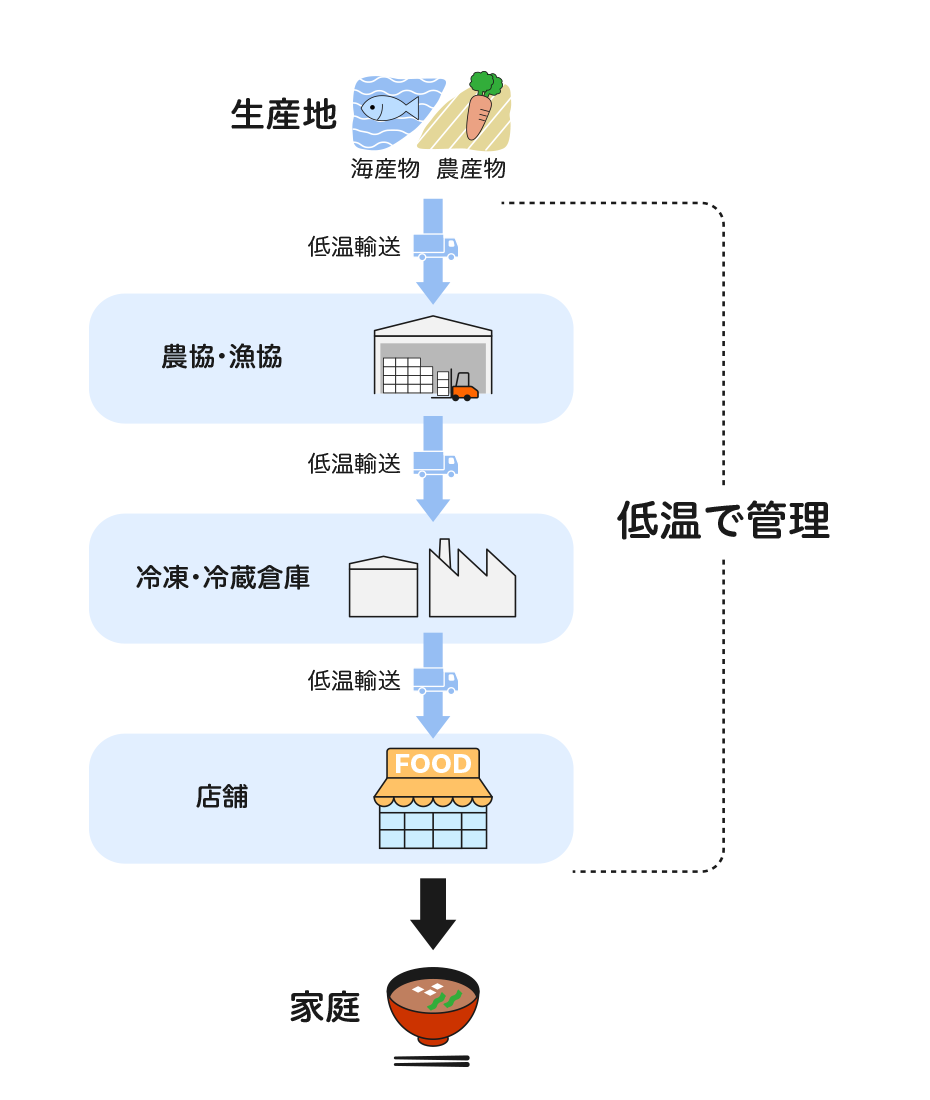

There are numerous products that require low-temperature control, such as fresh food and medicines. The logistics system that maintains product quality through cooling technologies during transportation from production areas and manufacturers, sales in stores or other locations, and deliveries to consumers is called the "cold chain."

For example, freezing and refrigeration at factories for shipping agricultural and livestock products, refrigerated trucks and aircraft for transporting them while maintaining their conditions, and freezers and refrigerated display cases installed in stores, including supermarkets and convenience stores, collectively constitute the cold chain.

The entire process is called the "cold chain" because individual component processes are interconnected like a chain under cold conditions, from production areas to consumers.

― Examples of cold chain ―Perishable foods

A rich dietary life sustained

by the cold chain

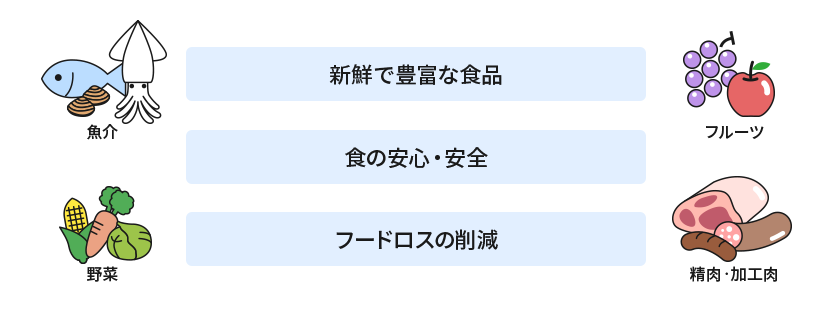

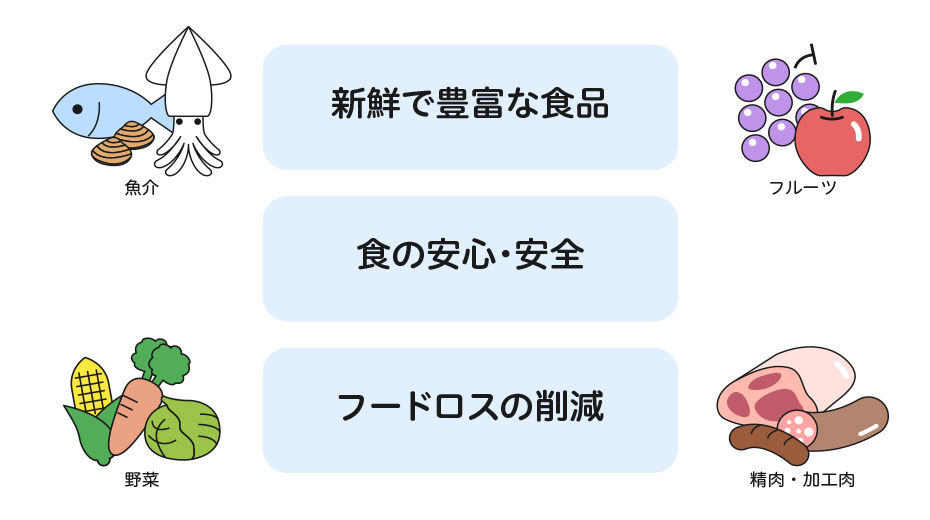

What would happen if there were no cold chain systems? Fresh food could only be transported short distances and would deteriorate quickly without refrigeration. The variety of food available to us would be limited, and food shortages would likely arise due to the lack of transportation from production areas to densely populated urban regions.

In the past, people living far from the ocean could only consume processed seafood, such as dried, salted, or miso-marinated products, as part of their daily diet. People living in mountainous areas can now enjoy fresh seafood sashimi thanks to the establishment of the cold chain supported by cooling technologies.

Today, we can enjoy a rich and varied diet featuring fresh food delivered from diverse production areas, including fresh meat, vegetables, fruit, and seafood arriving directly from fishing ports, with a sense of safety and security. We tend to take the cold chain for granted in our daily lives, yet it is an essential system that safely enriches our diet.

Why is it possible to cool food?

Let's focus on the cooling mechanism.

How do we cool food? We will explain the cooling mechanism using supermarket display cases, which are part of our everyday lives, as an example.

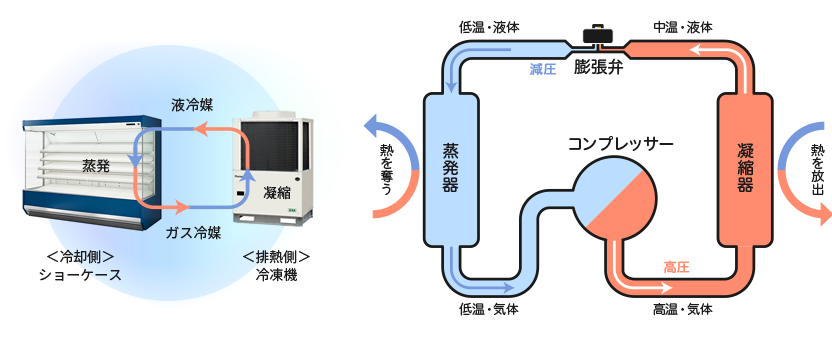

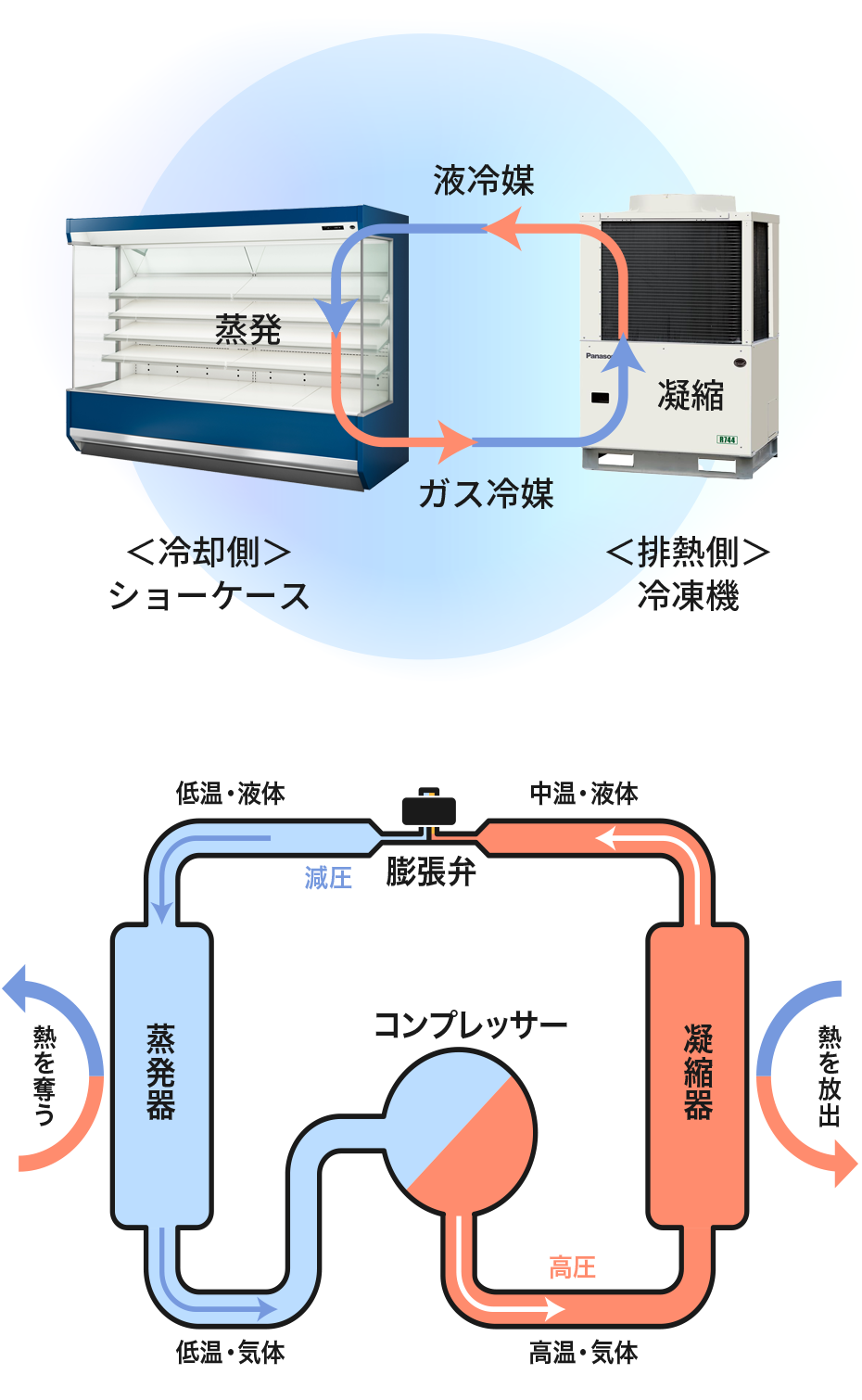

A very long copper pipe is routed along the back of a display case. Refrigerant liquid flowing through the pipe gasifies and cools the interior of the showcase by absorbing ambient heat. After cooling, the refrigerant circulates through the condensing unit connected to the pipe, is reused, and continues cooling the display case. As the refrigerant is reused, it transitions between gaseous and liquid states during circulation. These changes constitute the cooling mechanism.

Gas condenses (liquefies) when cooled. A familiar example of condensation is the formation of dew. Sweating (formation of dew) on windowpanes in winter is a phenomenon where water vapor in the air cools, transitions from a gas to a liquid, and becomes water. Conversely, liquid returns to gas through evaporation. Evaporation is a phenomenon where a liquid changes into gas by absorbing heat (vaporization heat) from the surrounding environment. A familiar example is sprinkling water in the summer. When you sprinkle water, it evaporates by absorbing heat from the ground surface, lowering its temperature and making you feel cooler. Display cases are cooled through the processes of condensation and evaporation.

A similar principle to this cooling mechanism is applied in air conditioners for cooling air. The condensing unit (the heat-exhausting side), which pairs with the display case (the cooling side), serves a similar function to the outdoor unit of an air conditioner. When subjected to high pressure, the refrigerant flowing through the copper pipe connecting the display case and the refrigeration system condenses (liquefies) and releases heat. When the pressure is reduced, it evaporates (vaporizes) and absorbs heat. We can maintain cooling in the display case by adjusting the pressures applied to the cooling side (display case) and the heat-exhausting side (refrigeration system).

CFCs, chemical substances, were previously used as a refrigerant. However, global regulations have been established, and its use has been completely abolished in Japan.

Chemical refrigerants used in condensing units and other equipment have been replaced with HFCs, which do not deplete the ozone layer, and further with natural refrigerants that have a lower impact on global warming.

― Cooling mechanism ―(Refrigeration cycle)

Relationships between temperature range

and palatability

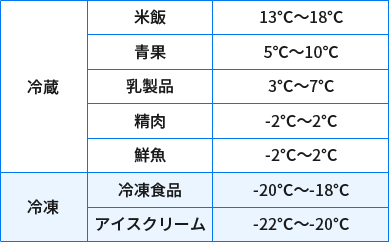

When cooling food, are you aware that optimal temperatures vary based on the type of food? For example, sandwiches and rice balls tend to harden if overcooled. On the other hand, meat quickly deteriorates when stored at a temperature ideal for sandwiches. High-milk-fat ice cream melts quickly, so it is frozen at a lower temperature than low-milk-fat ice cream.

As the above examples show, temperatures have a major impact on foodstuffs, making careful temperature control essential for both food safety and palatability. Therefore, a wide variety of display cases are available, tailored to the specific temperature requirements of individual foodstuffs. To highlight display cases for supermarkets, the Cold Chain Solutions Company offers over 1,200 types. We produce various models tailored to the temperature range and lighting colors even if they appear similar at first glance.

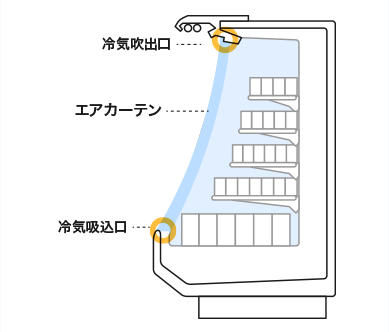

By the way, are you aware of how supermarket display cases are kept cool despite not having doors? They use an air curtain mechanism, blowing air from the upper to lower section to trap cool air and prevent it from escaping.

Guidelines for Storage Temperatures by Each Foods

*Inside Air Temperature Range of Panasonic Display Cases ( Japan Standard )

Mechanism of air curtain

Cold chain

and future lifestyles

The cold chain has evolved to preserve food freshness, but its functions extend beyond merely prolonging shelf life. In recent years, technologies that support food safety and taste have also advanced significantly.

For example, cooling technology plays a vital role when temporarily storing freshly cooked hot meals. From a HACCP perspective, it is crucial to quickly pass through the temperature range between 60℃ and 10℃, where bacteria proliferate most rapidly. To address this, specialized equipment has been developed to rapidly cool food by removing residual heat, as well as devices that can handle both cooling and freezing in a single unit.

Defrosting technology has also made great strides. Dedicated equipment now enables frozen foods to be thawed easily and effectively, minimizing cellular damage and reducing the amount of drip—liquid containing nutrients and flavor that escapes from meat or fish during thawing—while ensuring even defrosting.

Thanks to these innovations in cold chain technology, people across Japan can enjoy seasonal fresh produce and regional gourmet specialties with consistent quality, regardless of location.

By maintaining optimal temperatures tailored to each type of food, the cold chain helps ensure food quality and safety, reduces food waste through extended shelf life, enables long-distance distribution, and supports the growing demand for frozen foods. As society continues to change and consumer needs evolve, the cold chain will keep advancing to meet those challenges.